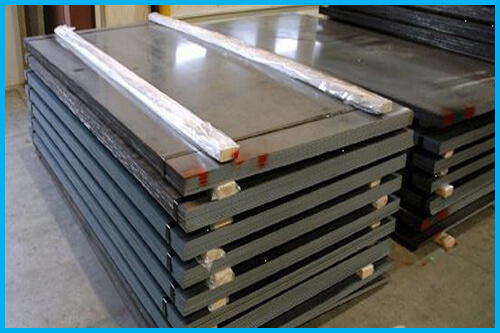

Looking for steel solutions that deliver unmatched durability in high-abrasion environments? Wear plates are engineered to withstand extreme wear, impact, and friction, making them essential for heavy-duty industrial applications. Buyers consistently choose wear plates for their exceptional hardness, long service life, and cost-saving performance, ensuring operations stay efficient while minimizing downtime.

Looking for steel solutions that deliver unmatched durability in high-abrasion environments? Wear plates are engineered to withstand extreme wear, impact, and friction, making them essential for heavy-duty industrial applications. Buyers consistently choose wear plates for their exceptional hardness, long service life, and cost-saving performance, ensuring operations stay efficient while minimizing downtime.

Why Buyers Prefer Wear Plates

When it comes to protecting equipment and extending the life of machinery, wear plates stand out as a reliable solution. Designed to resist abrasion and mechanical stress, wear plates allow businesses to operate with reduced maintenance costs and improved productivity.

Key benefits include:

-

Exceptional abrasion and impact resistance for harsh environments

-

Extended service life reduces replacement frequency

-

Easy to cut, weld, and fabricate for custom applications

-

Reduces operational downtime and maintenance costs

-

Consistent hardness across thickness for reliable performance

-

Suitable for heavy machinery, conveyors, chutes, and liners

Buyers across industries—from mining and construction to cement and steel manufacturing—rely on wear plates to ensure safety, durability, and cost-efficiency.

Technical Specifications of Wear Plates

Understanding the technical aspects of wear plates ensures buyers select the right grade and thickness for their applications.

Chemical Composition (Typical %)

-

Carbon (C): 0.25 – 0.45

-

Manganese (Mn): 0.50 – 1.50

-

Silicon (Si): 0.20 – 0.50

-

Chromium (Cr): 1.0 – 2.5

-

Nickel (Ni): 0.30 – 0.50

-

Molybdenum (Mo): 0.20 – 0.50

-

Phosphorus (P): ≤ 0.025

-

Sulfur (S): ≤ 0.025

This composition ensures wear plates maintain hardness and toughness under high stress.

Mechanical Properties

-

Hardness: 400 – 600 BHN (depending on grade)

-

Tensile Strength: 650 – 900 MPa

-

Yield Strength: 450 – 700 MPa

-

Elongation: 10 – 20%

Available Forms

-

Hot-rolled wear plates

-

Hardfaced or AR-coated plates

-

Cut-to-size or full-sheet plates

Applications

Wear plates are essential in industries where abrasion and impact are constant challenges:

-

Mining equipment liners and chutes

-

Cement plant hoppers and grinding mills

-

Earthmoving machinery and bulldozer blades

-

Conveyor belts and material handling systems

-

Steel and aluminum rolling mills

-

Waste processing and recycling machinery

International Standards

Wear plates meet rigorous global standards to ensure consistent quality and performance:

-

UNS: No direct designation (industrial wear steel category)

-

ASTM: ASTM A514, ASTM A517

-

ASME: ASME SA514, ASME SA517

-

DIN / EN: EN 10025-6, EN 10250-2

These certifications ensure buyers receive wear plates with proven strength, hardness, and toughness for critical applications.

Regional Buyer Focus

-

India: Mining, cement, steel, and construction industries

-

Germany: Heavy machinery and automotive sector

-

UK: Industrial processing and material handling

-

UAE: Oil & gas, construction, and mining projects

Why Buyers Should Partner with Vandan Steel & Engg.co

Partnering with a trusted supplier is key to securing high-quality wear plates. Vandan Steel & Engg.co provides:

-

Mill Test Certificates (MTCs) for complete traceability

-

Flexible minimum order quantities (MOQs) for diverse project sizes

-

Efficient domestic and international logistics

-

Expert technical support for fabrication, welding, and installation

-

Competitive pricing without compromising on quality

By choosing Vandan Steel & Engg.co, buyers gain reliable supply, technical expertise, and superior customer service for all wear plate requirements.

Secure Your Wear Plates Supply Today

For industrial operations that demand durability, reliability, and cost efficiency, wear plates deliver unmatched performance. Ensure your projects run smoothly with high-quality plates sourced from a trusted partner.

Vandan Steel & Engg.co

359 / 373, Flat -9, 2nd Floor, Minerva Mansion, Svp. Road, Khetwadi, Giragoan, Mumbai -400004

???? +91-8828813630

✉️ [email protected]

Contact us now to source premium wear plates tailored to your industrial and heavy-duty needs.